Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Acrylic, also known as plexiglass, has strong resistance to high and low temperature deformation, superior physical properties and good oxidation resistance. With the continuous development of social economy, Acrylic display racks have been widely used in our lives, and at the same time, they have also attracted the attention of customers. Customers can customize the acrylic display stand of their own products, which can not only display the product itself, but also reflect the culture and value of the brand.

Usually, the processing process of acrylic includes:

1.Cutting Material: According to the acrylic product size requirements, use a cuttig machine to cut to avoid material waste. APEX has dozens of cutting machines that can cut sheets of different sizes.

2.Engraving: After cutting, according to the customer's order requirements, engrave various complex patterns, text or LOGO, etc.

3.Punching: Acrylic can be punched directly with a drilling machine. According to the requirements on the processing drawings, it can be directly placed on the drilling machine and fixed, and the hole can be directly positioned and punched. We have many operators with many years of experience in acrylic processing, which can avoid damage to the acrylic sheet during the drilling process, thereby reducing unnecessary wear and tear.

4.Tear film: After the acrylic sheet leaves the factory, there will be a layer of protective film, and the sticker attached to the acrylic sheet must be torn off before hot bending and silk screen printing.

5.Grinding and polishing: After cutting, carving, and punching, the edges of acrylic are rough and may scratch your hands. Therefore, we can polish the surface of the Acrylic Display Stand to be as bright and smooth as crystal. Polishing is also divided into flame polishing machine, cloth wheel polishing machine and diamond polishing machine. Different products use different polishing methods.

6.Hot bending: Acrylic can be transformed into different shapes by hot bending. Hot bending is divided into overall hot bending and local hot bending.

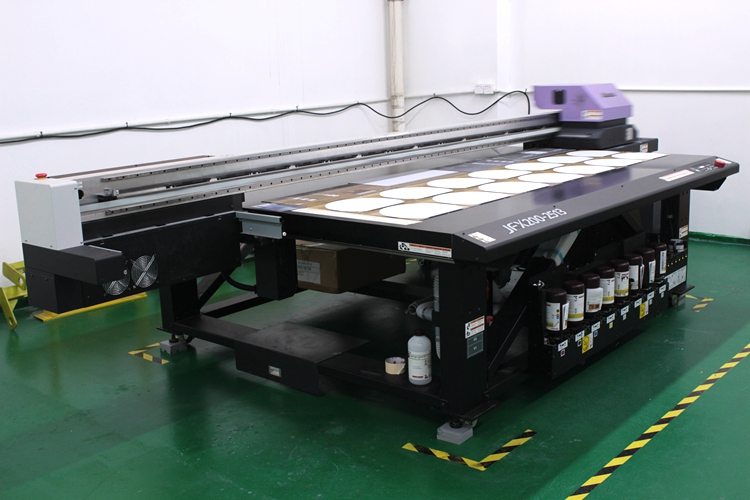

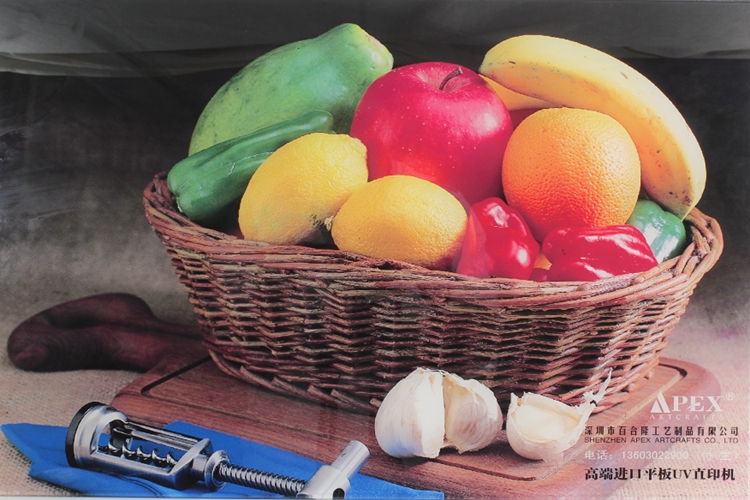

7.Printing: According to the needs of customers, we can do different printing on acrylic. Printing includes silk screen printing, bronzing, UV printing and stick graphic, etc.

8.Glueing: The glueing process is all operated by hand, so this process is a test of the craftsmanship of the workers. APEX has a special glueing line, and all the workers are experienced, which can avoid the occurrence of sticking, blistering, and weak glueing. Common glueing processes include butt joint, vertical glueing, bevel 45°bonding and surface glueing.

9.Assemble: Combine accessories to complete a complete product.

10.Packaging: After the assembly is completed, the final quality inspection of the entire product must be carried out.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.